The Actisense EMU-1 is a specialized analogue to NMEA 2000 Gateway which converts data from analogue engine gauges/senders into NMEA 2000. The marine engine gateway enables the sharing of engine data throughout the NMEA 2000 bus. It digitises analogue engine sensors, enabling NMEA 2000 display devices to monitor the connected engine(s) on a vessel.

The most important point to remember about the EMU-1 is that it is the senders and gauges that are important when trying to understand compatibility and not the engine model/manufacturer.

The reason for this is that it is fairly common for 2 identical engines to operate with different senders and gauges. If the configuration is done from engine make/model, then the chance of them being accurate is fairly low, especially if they are not the ‘factory’ gauges.

What can I measure with my EMU-1?

When we talk about “Engine Monitoring”, what exactly are we referring to?

When we originally launched the EMU-1 NMEA 2000 Engine Monitoring Unit back in 2013, we interviewed marine electronics technicians and installers to ask what valuable data they would want to collect and monitor on their customers’ boats. The list was long!

One of the biggest highlights was the ability to show this information on an onboard multifunction display, all made possible by NMEA 2000 integration.

The EMU-1 now provides support for 6 gauge sender inputs, 4 alarm inputs and 2 tacho inputs. But what can you monitor with it? Below is a list of gauge and alarm references with the associated PGN that can be used on your NMEA 2000 network.

Gauges supported by inputs

| Gauge reference | PGN associated |

| Engine Temperature | 127489 |

| Engine Oil Pressure | 127489 |

| Engine Oil Temperature | 127489 |

| Engine Coolant Pressure | 127489 |

| Engine Boost Pressure | 127488 |

| Engine Fuel Pressure | 127489 |

| Engine Tilt/Trim | 127488 |

| Fluid Level – Fuel | 127505 |

| Fluid Level – Fresh water | 127505 |

| Fluid Level – Waste Water | 127505 |

| Fluid Level – Live Well | 127505 |

| Fluid Level – Oil | 127505 |

| Fluid Level – Black Water | 127505 |

| Transmission Oil Pressure | 127493 |

| Transmission Oil Temperature | 127493 |

Alarms capable of output onto N2K Bus

| Check Engine | 127489 |

| Over Temperature | 127489 |

| Low Oil Pressure | 127489 |

| Low Oil Level | 127489 |

| Low Fuel Pressure | 127489 |

| Low System Voltage | 127489 |

| Low Coolant Level | 127489 |

| Water Flow | 127489 |

| Water in Fuel | 127489 |

| Charge Indicator | 127489 |

| Preheat Indicator | 127489 |

| High Boost Pressure | 127489 |

| Rev Limit Exceeded | 127489 |

| EGR System | 127489 |

| Throttle Position Sensor | 127489 |

| Engine Emergency Stop Mode | 127489 |

| Warning Level 1 | 127489 |

| Warning Level 2 | 127489 |

| Power Reduction | 127489 |

| Maintenance Needed | 127489 |

| Engine Comm Error | 127489 |

| Sub or Secondary Throttle | 127489 |

| Neutral Start Protect | 127489 |

| Engine Shutting Down | 127489 |

| Check Transmission | 127493 |

| Transmission Over Temperature | 127493 |

| Transmission Low Oil Pressure | 127493 |

| Transmission Low Oil Level | 127493 |

| Transmission Sail Drive | 127493 |

On top of all these, the EMU can also be configured for:

- 2 x Tacho/RPM inputs which provide Engine Speed (127488) – can also be used as a trigger for monitoring Engine Hours (PGN 127489).

- Battery Voltage: The DC voltage the EMU-1 measures at its Power input can be set to either Battery Voltage (127508) or Engine Alternator Potential (127489).

What next for the EMU-1?

We have two AUX ports that are currently unused. What else would you like to see monitored by the EMU-1? Click here to send us your requests!

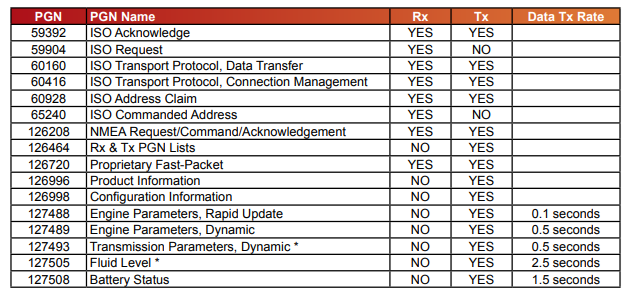

EMU PGN Output

The EMU-1 will output standard NMEA 2000 engine, transmission and fluid level PGNs that will be understood by any NMEA 2000 MFD.

How to power the Engine Monitoring Unit?

The EMU-1 should only be connected to a DC Power supply. The device can operate between 9 – 35 VDC, meaning it is capable of full operation on a typical 12V supply. When connecting the power to the EMU-1, it should be sharing the same power and ground as that of the engines. The ground of the EMU-1 gauges and the EMU-1 power supply must be common to ensure that no ground loops are created.

Dual Engine Power Supply

When monitoring two engines using a single EMU-1, both engines and the EMU-1 must share the same power supply if the gauges are to remain in circuit. If a separate power supply must be used for each engine, either a separate Engine Monitoring Unit is required for each engine or the gauges will need to be removed for the EMU-1 to correctly monitor the sensors of both engines

How do you configure my EMU-1?

An Actisense NGT-1 or NGX-1 is required in conjunction with Actisense Toolkit to configure your EMU-1. This NGT-1 or NGX-1 is the gateway device between the PC and the NMEA 2000 network. The NGX-1-USB or NGT-1-USB is the preferred variant here due to the easy plug-and-play nature of the USB.

Further configuration of the gauges can be done with the custom gauge manager, which is designed to support any gauges which are not in the default EMU-1 library. Download the guide to custom gauge manager.