Additional information

| Weight | 0.4 kg |

|---|---|

| Dimensions | 23.5 × 15.5 × 6.5 cm |

The Actisense EMU-1 is a specialized analogue to NMEA 2000 Gateway which converts data from analogue engine gauges/senders into NMEA 2000 data. The EMU-1 enables the sharing of engine data throughout the NMEA 2000 bus. It digitises analogue engine sensors, enabling NMEA 2000 display devices to monitor the connected engine(s) on a vessel.

The EMU-1 can monitor vital engine parameters such as temperature, pressure RPM and fluid levels from up to two engines.

NOW INCLUDES SUPPORT FOR TILT & TRIM TABS!

Fully NMEA 2000 Certified

The EMU-1 has a PC-based configuration tool that allows the settings inside the EMU-1 to be changed to best suit the engine it is working with, making it a flexible solution for many engine makes and models.

An Actisense PC to NMEA 2000 Gateway (NGX-1/NGT-1) is required to configure the EMU-1.

The NGX-1 or NGT-1 must be used to update the firmware, connect the Toolkit and display data on a PC for diagnostic and information purposes, using NMEA Reader. Please visit the NGX-1 page and/or NGT-1 page for product details.

FEATURES

BENEFITS

(Part number/s)

CONFIGURATION INFORMATION

Every EMU-1 MUST be configured to work with each installation. Please visit the downloads page to download the Actisense toolkit.

The digitising of analogue data is something we see more and more of as the marine environment progresses. With the release of engines that are NMEA 2000 harnessed already, the use of NMEA 2000 systems and MFD’s increased. Of course, if the vessel has existing analogue engines that aren’t digital harness capable, there needs to be a solution.

The expensive solution is to remove the engines are replace them with newer digital ready engines… which isn’t exactly cost effective. The budget sensitive solution is to use the EMU-1 for analogue to digital conversion.

A prime example of this is a typical set-up of a duel diesel engine that’s purely analogue, and the owner has an NMEA 2000 network with GPS, AIS, MFD etc… The MFD is capable of displaying various engine parameters such as temp, oil pressure, RPM, tilt/trim, transmission position, fuel level and the owner wants this info from his engines.

The EMU-1 is ideal for this scenario. The device is connected to existing sender/gauges and receives the analogue signals. Once the device is configured for the required parameters the user wants to monitor, the analogue signals are converted to NMEA 2000 data, which is then output in various PGNs.

With 6 gauge inputs, 4 alarm and 2 tach inputs, the EMU-1 is capable of supporting 2 engines with one device (although this is limited by the number of inputs). However for those who want to monitor just a couple of parameters from each engine in a very cost friendly method, the EMU-1 is perfect. Alternatively, for those who need to monitor more parameters from each engine, then 2 EMU-1s (one on each engine) can be installed.

| Power Supply | |

| Supply Voltage | 9 to 35V DC |

| Supply Current | Typically < 25mA @ 12V DC |

| Supply Protection | Continuous reverse polarity protection and load dump protection (meets SAE J1113) |

| Supply Connector | Pluggable 2-way screw terminal, 3.5mm pitch |

| Supply Voltage (NMEA 2000 Port) | 9 to 29V DC |

| Supply Current (NMEA 2000 Port) | < 20mA @ 12V DC from NMEA 2000 bus |

| Load Equivalent Number (LEN) | 1 |

| Supply Protection (NMEA 2000 Port) | Continuous reverse polarity protection and overvoltage protection to 40V |

| NMEA 2000 Port – In/Out | |

| Compatibility | Fully NMEA 2000 certified |

| Galvanic Isolation | 2500V input to ground, 1500V output to ground using ISO-Drive |

| Speed / Baud Rate | 250kbps |

| NMEA 2000 Connector | M12 male (A coded) connector |

| Gauge Inputs | |

| Voltage Range | 0 to 35V DC |

| Input Impedance | > 50kΩ |

| Sender Feed | 0, 4 or 18mA |

| Accuracy | <= 2% |

| Input Connector | Pluggable 6-way screw terminal, 3.5mm pitch |

| Input Protection | Overvoltage protection to ±40V |

| Alarm Inputs | |

| Voltage Range | 0 to 37V DC |

| Input Impedance | > 50kΩ |

| Threshold Voltage | Configurable, default is 5V |

| Alarm Polarity | Configurable, default is alarm on low input |

| Accuracy | <= 2% |

| Input Connector | Pluggable 4-way screw terminal, 3.5mm pitch |

| Input Protection | Overvoltage protection to ±40V |

| Tacho Inputs | |

| Voltage Range | ±3 to ±60V |

| Input Impedance | > 100kΩ to ground |

| Input Pulse Range | 4 to 50,000Hz |

| Accuracy | <= 1% |

| Sender Compatibility | Ignition coil, alternator (“W”, “R” or “AC”) terminal, hall effect, VR or inductive sender |

| Threshold | Automatically adjusts to signal level |

| Input Connector | Pluggable 4-way screw terminal, 3.5mm pitch |

| Input Protection | Can withstand an ignition pulse to ±500V |

| Engine Log | |

| Engine Hours | 2 separate engine hour logs internally connected to the tacho Inputs. Hours are logged when RPM is present, stored in non-volatile memory |

| Mechanical | |

| Housing Material | Polycarbonate |

| Protective Lid Material | Polycarbonate |

| Sealing Materials | Expanded silicone foam gasket, closed cell polyurethane splash guard and ePTFE waterproof vent |

| Dimensions | 127mm (L) x 112mm (W) x 48mm (H) |

| Weight | 250g |

| Mounting | 4 x 3.5mm lugs to allow panel mount with self tapping s/s screws (included), optional DIN Rail mount available on request |

| Approvals and Certifications | |

| Fully NMEA 2000 Certified | |

| EMC | EN 60945 (sections 9 & 10) |

| Environmental Protection | IP66 (PCB housing) |

| Operating Temperature | -20°C to +55°C |

| Storage Temperature | -30°C to +70°C |

| Recommended Humidity | 0 – 93% RH |

| Guarantee | 3 years |

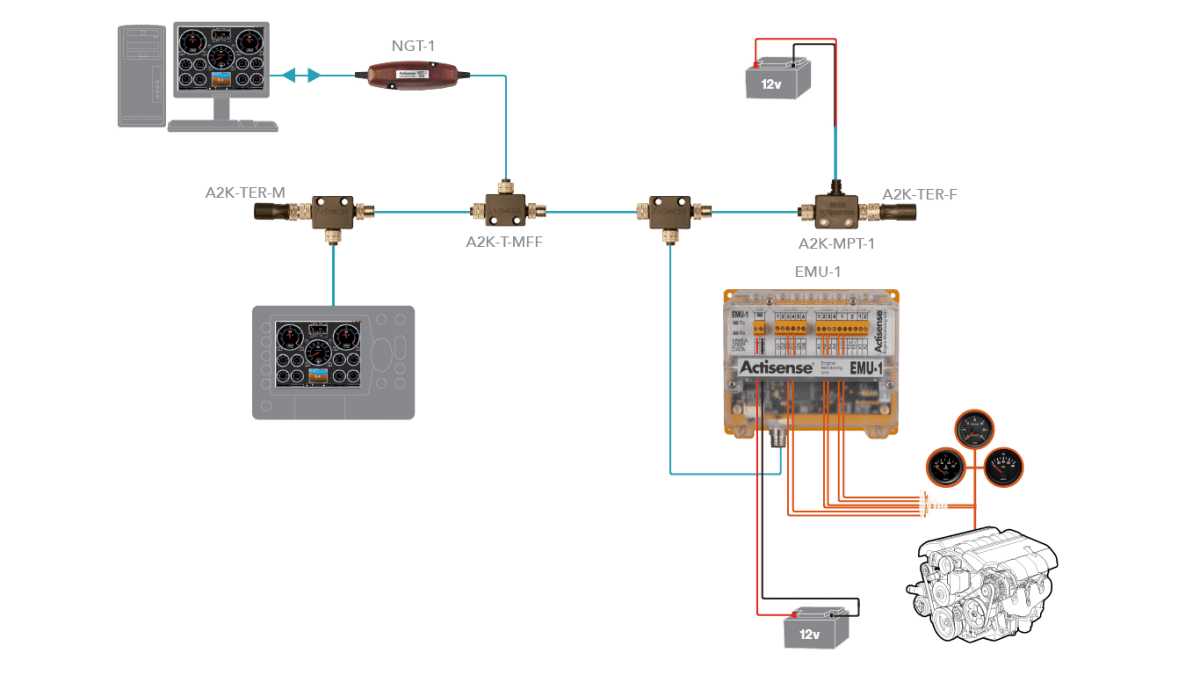

NETWORK DIAGRAM

NEW EMU-1 FIRMWARE IS AVAILABLE:

To upgrade to 1.106 firmware, download and install the latest version of Toolkit from our ‘Useful Downloads’ link below.

Actisense is dedicated to providing up-to-date software and resources for our products. Here are some useful tools and documentation to help you make the most of your product:

FAQ

Here are some Frequently Asked Questions about the EMU-1.

Need more help? Visit our Support Centre.

Click here to read our delivery and returns policies.

Click here for our E-Commerce Terms of Sale.

If ordering through your local distributor/dealer, please see their Terms of Sale.

Fully NMEA 2000 Certified

The EMU-1 has a PC-based configuration tool that allows the settings inside the EMU-1 to be changed to best suit the engine it is working with, making it a flexible solution for many engine makes and models.

An Actisense PC to NMEA 2000 Gateway (NGX-1/NGT-1) is required to configure the EMU-1.

The NGX-1 or NGT-1 must be used to update the firmware, connect the Toolkit and display data on a PC for diagnostic and information purposes, using NMEA Reader. Please visit the NGX-1 page and/or NGT-1 page for product details.

FEATURES

BENEFITS

(Part number/s)

CONFIGURATION INFORMATION

Every EMU-1 MUST be configured to work with each installation. Please visit the downloads page to download the Actisense toolkit.

The digitising of analogue data is something we see more and more of as the marine environment progresses. With the release of engines that are NMEA 2000 harnessed already, the use of NMEA 2000 systems and MFD’s increased. Of course, if the vessel has existing analogue engines that aren’t digital harness capable, there needs to be a solution.

The expensive solution is to remove the engines are replace them with newer digital ready engines… which isn’t exactly cost effective. The budget sensitive solution is to use the EMU-1 for analogue to digital conversion.

A prime example of this is a typical set-up of a duel diesel engine that’s purely analogue, and the owner has an NMEA 2000 network with GPS, AIS, MFD etc… The MFD is capable of displaying various engine parameters such as temp, oil pressure, RPM, tilt/trim, transmission position, fuel level and the owner wants this info from his engines.

The EMU-1 is ideal for this scenario. The device is connected to existing sender/gauges and receives the analogue signals. Once the device is configured for the required parameters the user wants to monitor, the analogue signals are converted to NMEA 2000 data, which is then output in various PGNs.

With 6 gauge inputs, 4 alarm and 2 tach inputs, the EMU-1 is capable of supporting 2 engines with one device (although this is limited by the number of inputs). However for those who want to monitor just a couple of parameters from each engine in a very cost friendly method, the EMU-1 is perfect. Alternatively, for those who need to monitor more parameters from each engine, then 2 EMU-1s (one on each engine) can be installed.

| Power Supply | |

| Supply Voltage | 9 to 35V DC |

| Supply Current | Typically < 25mA @ 12V DC |

| Supply Protection | Continuous reverse polarity protection and load dump protection (meets SAE J1113) |

| Supply Connector | Pluggable 2-way screw terminal, 3.5mm pitch |

| Supply Voltage (NMEA 2000 Port) | 9 to 29V DC |

| Supply Current (NMEA 2000 Port) | < 20mA @ 12V DC from NMEA 2000 bus |

| Load Equivalent Number (LEN) | 1 |

| Supply Protection (NMEA 2000 Port) | Continuous reverse polarity protection and overvoltage protection to 40V |

| NMEA 2000 Port – In/Out | |

| Compatibility | Fully NMEA 2000 certified |

| Galvanic Isolation | 2500V input to ground, 1500V output to ground using ISO-Drive |

| Speed / Baud Rate | 250kbps |

| NMEA 2000 Connector | M12 male (A coded) connector |

| Gauge Inputs | |

| Voltage Range | 0 to 35V DC |

| Input Impedance | > 50kΩ |

| Sender Feed | 0, 4 or 18mA |

| Accuracy | <= 2% |

| Input Connector | Pluggable 6-way screw terminal, 3.5mm pitch |

| Input Protection | Overvoltage protection to ±40V |

| Alarm Inputs | |

| Voltage Range | 0 to 37V DC |

| Input Impedance | > 50kΩ |

| Threshold Voltage | Configurable, default is 5V |

| Alarm Polarity | Configurable, default is alarm on low input |

| Accuracy | <= 2% |

| Input Connector | Pluggable 4-way screw terminal, 3.5mm pitch |

| Input Protection | Overvoltage protection to ±40V |

| Tacho Inputs | |

| Voltage Range | ±3 to ±60V |

| Input Impedance | > 100kΩ to ground |

| Input Pulse Range | 4 to 50,000Hz |

| Accuracy | <= 1% |

| Sender Compatibility | Ignition coil, alternator (“W”, “R” or “AC”) terminal, hall effect, VR or inductive sender |

| Threshold | Automatically adjusts to signal level |

| Input Connector | Pluggable 4-way screw terminal, 3.5mm pitch |

| Input Protection | Can withstand an ignition pulse to ±500V |

| Engine Log | |

| Engine Hours | 2 separate engine hour logs internally connected to the tacho Inputs. Hours are logged when RPM is present, stored in non-volatile memory |

| Mechanical | |

| Housing Material | Polycarbonate |

| Protective Lid Material | Polycarbonate |

| Sealing Materials | Expanded silicone foam gasket, closed cell polyurethane splash guard and ePTFE waterproof vent |

| Dimensions | 127mm (L) x 112mm (W) x 48mm (H) |

| Weight | 250g |

| Mounting | 4 x 3.5mm lugs to allow panel mount with self tapping s/s screws (included), optional DIN Rail mount available on request |

| Approvals and Certifications | |

| Fully NMEA 2000 Certified | |

| EMC | EN 60945 (sections 9 & 10) |

| Environmental Protection | IP66 (PCB housing) |

| Operating Temperature | -20°C to +55°C |

| Storage Temperature | -30°C to +70°C |

| Recommended Humidity | 0 – 93% RH |

| Guarantee | 3 years |

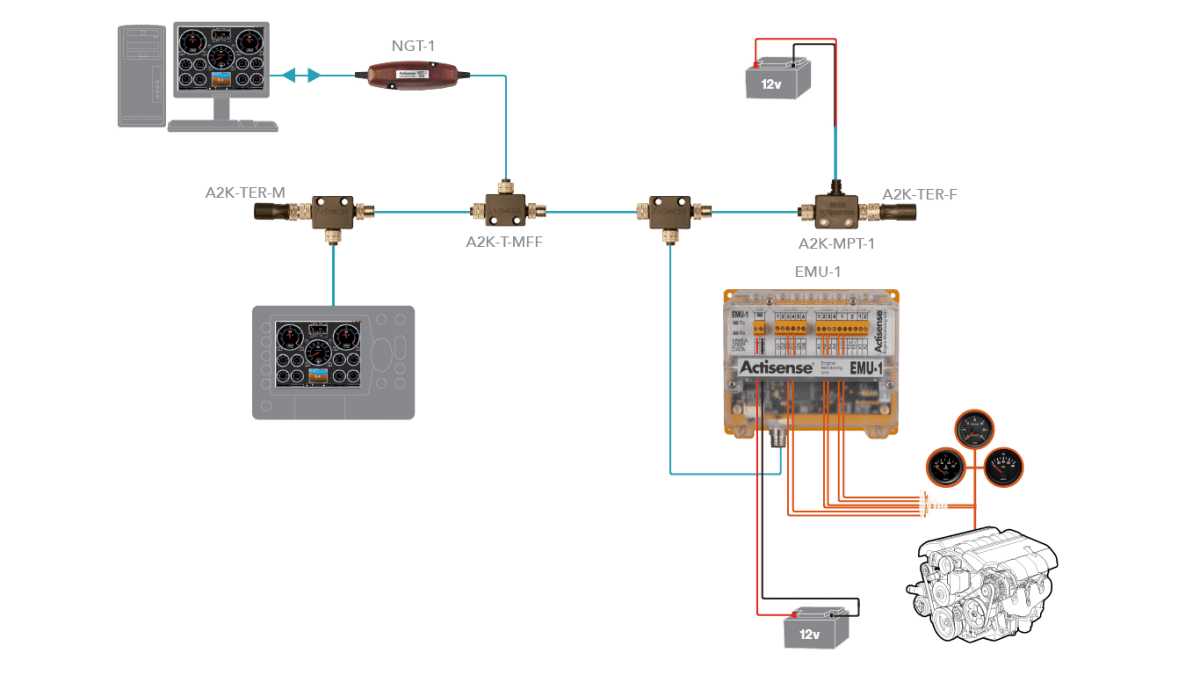

NETWORK DIAGRAM

NEW EMU-1 FIRMWARE IS AVAILABLE:

To upgrade to 1.106 firmware, download and install the latest version of Toolkit from our ‘Useful Downloads’ link below.

Actisense is dedicated to providing up-to-date software and resources for our products. Here are some useful tools and documentation to help you make the most of your product:

FAQ

Here are some Frequently Asked Questions about the EMU-1.

Need more help? Visit our Support Centre.

Click here to read our delivery and returns policies.

Click here for our E-Commerce Terms of Sale.

If ordering through your local distributor/dealer, please see their Terms of Sale.